- Home

- Review

- Discontinued

- High Resolution Textile Printing Machine, YD-1800SE

High Resolution Textile Printing Machine, YD-1800SE

This product has been discontinued and removed from our shelves.

The textile printing machine is a selection of digital printer designed to print on various woven and knitted fabrics, including cotton, linen, silk, nylon and dacron fabrics. Eight StarFire SG1024 printheads deliver maximum printing width up to 3.2m and maximum speed of 125㎡ per hour. These industrial grade stainless steel inkjet print heads with reliable performance allow for long term continuous operation without failure. Imported high quality core components, such as Panasonic servo motor, ensure printing precision. Genuine original NSK bearings provide the textile printer with extended service life, reduce noise and minimized failure rate.

CE compliant, ecofriendly printing ink

The textile printing machine employs CE compliant ecofriendly printing ink which is harmless to human health and the environment.

StarFire SG1024 printhead

The textile printer is installed with 8 StarFire SG1024 industrial inkjet printheads made from stainless steel. The printhead is extensively used in European printworks, and is suitable for continuous, large quantity printing.

1.8m, 2.6m, 3.2m printing width options

With multiple max. printing width for option, the large format printer meets the varied printing demands in fashionable clothing and home textile industries.

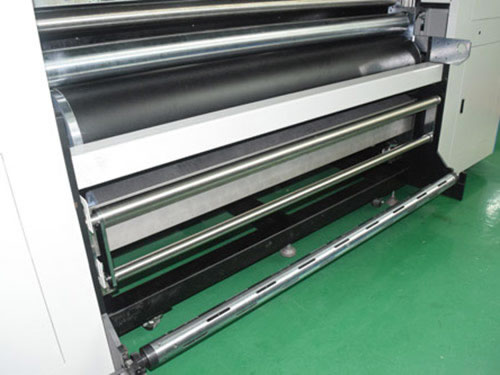

Fabric conveying system

1. Due to the specialized belt conveying system, the textile printing machine realizes tension-free delivering of fabrics, weather that is stretch fabric or non-stretch fabric.

2. Automated belt washing and drying greatly improves working efficiency and avoids belt damages caused by human factor

3. Belt guiding system is available to keep the belt always in the middle position, so as to ensure printing precision and extend belt lifespan

4. The belt can be conveniently replaced without disassembly of the digital textile printer.

Ink scraper system

The textile printing machine is designed with an innovative ink scraper system to remove excessive ink from the print head so as to prevent printhead clogging.

Fabric winding and rewinding units

Available with automated constant tensile winding and rewinding units, the industrial inkjet printer prevents wrinkling of printed fabrics.

Drying system

The textile printing machine features a medium-wave infrared heater with multi-tube configuration, allowing for immediate drying of printed items. Interlock control system for printing and drying units ensures high efficiency and stability as well as simple usage. Optional independent drying system is available as well.

| Max. printing width | 1.8m, 2.6m, 3.2m |

| Fabric thickness | 0-30mm |

| Print head | StarFire SG1024 industrial inkjet printhead, with integral heater and ink circulation system |

| Printing resolution | 400dpi |

| Printing speed | High speed mode: 3 pass-125 ㎡ /h; Normal working mode: 6 pass-105 ㎡ /h; High precision mode: 8 pass-65 ㎡ /h |

| RIP software | Professional RIP software exclusive for textile printing machines |

| Image format / color model | Image format: JPEG, TIFF, BMP Color model: RGB, CMYK |

| Applications | Various woven and knitted fabrics, including cotton, linen, silk, nylon and dacron fabrics |

| Ink colors | Ten colors for option: Cyan, magenta , yellow, black, light cyan, light magenta, sapphire blue, orange, red, gray |

| Printing ink type | Acid dye ink, active dye ink, disperse dye ink, pigment ink |

| Dimension (L*W*H) | 4.3*1.9*1.9 (m) |

| Weight | 2.5t |

| Power consumption | 25KW |

| Power supply | 380VAC±5%, three phase five wire, 50HZ±2% |

| Compressed air | Air flow ≥ 0.6m³/min, air pressure ≥ 8kg |

| Operating environment | Temperature: 20-30 ℃ Relative humidity: 50-80% |